LPG INJECTORS

( number of products: 154 )In sequential vapor-phase gas power systems for the engine, an indispensable component is the mechanical gas injector responsible for correct fuel dosage, exhaust emissions, correct operation of the system. They are divided into several types related to their construction m.in.: piston, disc, diaphragm, lever.

Proper selection of the right injector depends on many factors. One is the injector speed-the most common value quoted by manufacturers is the opening and closing time expressed in milliseconds. These values, depending on the actuator element of the injector, the materials used for construction, and thus the price, are in the range of approx. 4 ms to a value of less than one millisecond. To maintain proper operation of the gas installation, it should be set so that the gas injection time is longer than the petrol by 0.5 ms to 1.5 ms. In most of the newer cars with indirect injection, even this slower injector can be taken into account without any problems because the injection times of gasoline at idle oscillate within 3 ms. Paradoxically, it is the older cars, as a consequence of the use of fuel supply systems such as semi-sequentials or full groups, that pose a lot of problems. By choosing an insufficiently fast injection rail, an inexperienced gas fitter will have a lot of trouble setting the right fuel dose at idle. Manufacturers in this case have come out ahead by offering in the software of their products the option of full groups-when selected, the gas controller treats 2 gasoline injection cycles as one long one giving the slower injectors a chance to work properly. However, this is not effective in every case.

Hand in hand with the speed of operation is the precision that is responsible for equal spending and the repeatability of the injector on each section, which must be the same over the entire speed and load range of the engine. The tolerance of the difference must not be more than 5%. If this condition is not met, there may be problems with erratic engine operation, ignition loss and increased combustion. There are several methods to diagnose an injector for its output. The most popular is the measurement of the stroke of the working element on all sections of the injector consisting in the measurement with a micrometer sensor. This method is unfortunately not very precise, with a large measurement error. However, it is very helpful in the initial inspection of the injector, as well as the adjustment after regeneration of the strip. The most effective method is the dynamic measurement of the output of individual injection sections carried out with devices such as ABtest.

A very important feature when choosing an injector is its performance. The main parameter that defines it is the power (hp or KW) per cylinder. Manufacturers usually quote this value at 1 bar. However, it should be noted that some regulators operate in a different range, for example, the minimum pressure value possible to set is 1.4 bar. A universal solution is the use of calibration nozzles, which can be adjusted to individual needs without having to replace entire injection bars. The problem begins when the customer decides on an injector dedicated to a specific car's power, and it turns out to be too little or too powerful. The selection of the wrong one can be known when the difference in gas injection time is not within the limits previously mentioned (0.5 ms to 1.5 ms). In this case, there may be "injector looping" at low revs if the injector is too efficient or at high revs when it is not efficient enough. This results in abnormal operation of the engine, ignition of the check engine light and even engine damage caused by too high combustion temperature of the poor lpg and air mixture.

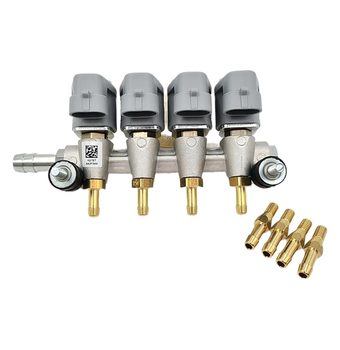

With the correct selection of a gas system component such as an injector, its location is also decisive. It is dictated by installation aesthetics and technical factors m.in. identical and as short as possible length of the pipes supplying gas to the intake manifold. However, manufacturers have a wide range: from single injectors to 2,3,4,6 cylinder lists. Important features that should determine the choice are: the ability to calibrate and disassemble-essential when regenerating a worn or contaminated injector.

The final factor in classifying injectors is their quality and price, which do not always go hand in hand. When choosing an lpg injector, it is best to follow user reviews and experienced installers. Very fast and precise injectors are usually susceptible to poor gas quality and necessitate the use of top quality filters with separator. More resistant to dirt, cheaper, however, do not give such high precision lpg dosing. Modern injectors are designed to offer high performance such as high precision and linearity, outstanding reliability and durability.

When it comes to verifying the correctness of the selection of the vapor phase gas injector, the car user unfortunately can not diagnose much. Only his observations related to the malfunction of the engine in the car manifested by a decrease in power, uneven operation at idle or jerking during acceleration may be the result of an error in the completion of the lpg system. The final diagnosis should be made by a qualified assembly plant equipped with the appropriate knowledge, measuring and diagnostic equipment.

The gas injector is the executing element of the enrichment and fuel mixture control algorithms. Only its correct operation allows the gas system to be properly calibrated and operate correctly throughout its lifetime.

For connecting single injectors in our offer you will find strips and bodies. Repair kits are also available to replace components that wear out without replacing the entire injector.

In our offer you will find injectors of such brands as: AC STAG, KME, LPG TECH, AEB, VALTEK, LANDI RENZO, BARRACUDA,HANA, OMVL, MATRIX, LOVATO AND BRC BRANDED WITH OMVL LOGO.